Unveiling Wrench Wizardry: A Comprehensive Expedition into Types, Applications, and Geotextile Integration

Wrenches, the timeless companions of mechanics, have etched their place in the mechanical world for centuries. From securing bolts to orchestrating complex assemblies, these versatile tools remain irreplaceable. This article takes an in-depth exploration into the various types of wrenches, their applications, and a surprising connection to geotextile materials.

Navigating the Wrench Landscape:

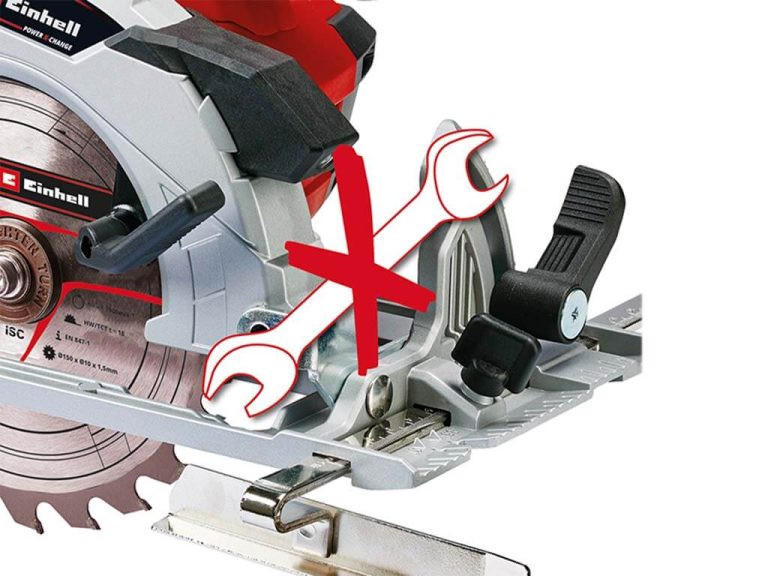

Wrenches come in various types, each meticulously designed for specific tasks. Adjustable wrenches, combination wrenches, socket wrenches, torque wrenches, and pipe wrenches are common variants, offering flexibility and precision tailored for different mechanical applications.

Unlocking the Applications of Wrenches:

Wrenches play a pivotal role in numerous industries and tasks. From automotive repairs to the assembly of towering structures, these tools are indispensable. Plumbers rely on specialized wrenches for pipe fittings, while home maintenance enthusiasts consider them essential for a variety of DIY projects.

The Unseen Bond: Wrenches and Geotextile Materials:

In an unexpected alliance, geotextile materials used in civil engineering and construction projects find a connection with wrenches. Specialized wrenches are employed to tighten bolts and nuts on geotextile-related installations, ensuring stability and durability.

Wrenches in Unconventional Roles: Innovative Applications:

Beyond their traditional roles, wrenches have found innovative uses in various industries. Precision torque wrenches are crucial in aerospace for assembling delicate components, and the renewable energy sector relies on specialized wrenches for maintaining and repairing wind turbines and solar panels.

In Conclusion: Wrenches as Timeless Artifacts in Mechanical Evolution:

Wrenches, with their adaptability, continue to be indispensable in various industries. From traditional roles like automotive repairs to cutting-edge applications in aerospace and renewable energy, these tools evolve alongside technological advancements. The unexpected connection between wrenches and geotextile materials showcases their adaptability and significance in diverse fields, solidifying their status as a cornerstone in the worlds of mechanics and construction.

Relevant Information About Valve

When comparing Ball Valve vs Butterfly Valve, both are commonly used in fluid control systems but offer distinct advantages based on application requirements. Ball valves provide quick quarter-turn operation, tight shut-off, and are versatile in various industries. They are ideal for on/off service and are capable of handling high-pressure applications. On the other hand, Butterfly valves are lightweight, cost-effective, and quick to operate, making them preferable for large flow applications where space is limited. The choice between these valves depends on factors like flow control needs, pressure ratings, space constraints, and the specific demands of the system, ensuring optimal performance and efficiency in fluid handling processes.