Mastering Precision: Exploring Grinding Techniques and Geogrid Integration

Within the domain of construction and material refinement, grinding stands as a crucial process that sculpts refines, and elevates various materials to meet specific standards. Whether in manufacturing, construction, or environmental restoration, grinding remains pivotal in achieving desired outcomes. Let’s delve into the intricacies of grinding, its expansive applications, and its seamless integration with geogrid technology.

Grasping the Essence of Grinding

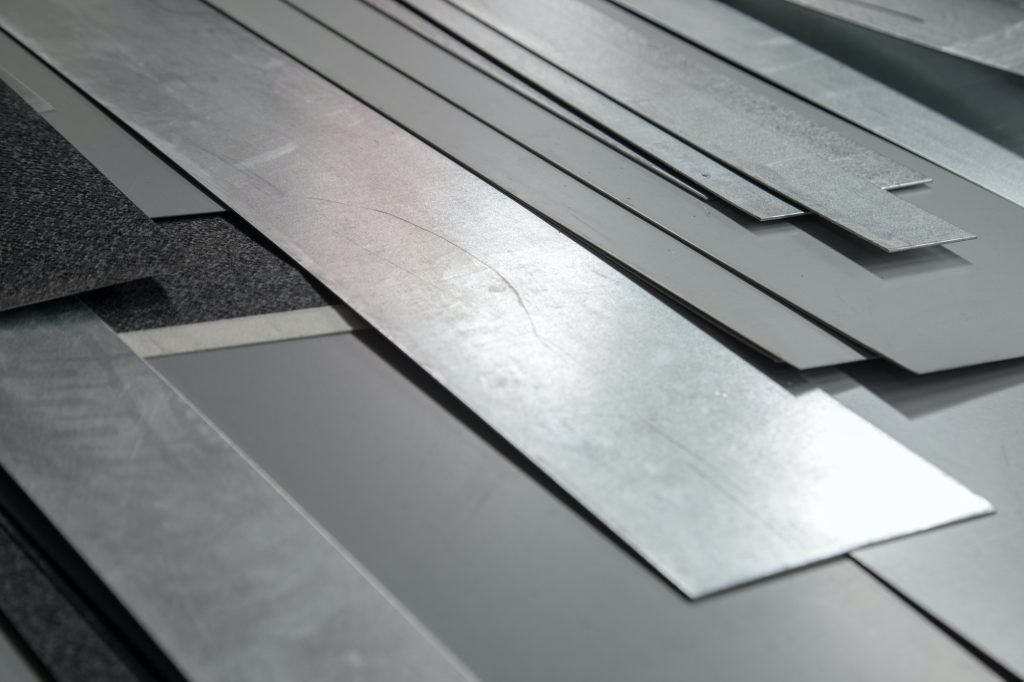

Grinding involves a machining process that utilizes abrasive wheels or tools to meticulously remove excess material or create refined finishes on a workpiece. By exerting force on the material surface, abrasive particles sculpt small chips, ultimately shaping the desired form, size, or surface texture.

Applications Spanning Industries

- 1. Manufacturing: Crucial for precision machining of metals, ceramics, and composites, grinding is instrumental in producing components with precise tolerances for industries such as aerospace, automotive, and electronics.

- 2. Construction: Integral in construction for leveling uneven surfaces, polishing concrete floors, and eliminating imperfections, contributing to enhanced durability and aesthetic appeal.

- 3. Mining and Material Processing: Essential in mineral processing to liberate valuable minerals from ore, enhancing extraction efficiency and reducing energy consumption in downstream processes.

- 4. Environmental Remediation: In environmental applications, grinding aids in soil remediation by breaking down contaminants, facilitating their removal, and improving soil quality.

Varied Range of Grinding Techniques

Grinding techniques vary based on the material being worked on and the desired outcome. Surface grinding, cylindrical grinding, centerless grinding, and precision grinding are among the common methods, each tailored to specific applications and materials.

Augmenting Applications with Geogrid Integration

Geogrids, a type of geosynthetic material, find extensive use in civil engineering for soil stabilization, erosion control, and reinforcement. When integrated with grinding processes, geogrids act as reinforcing agents, enhancing the structural integrity of surfaces. For instance, in road construction, the fusion of grinding and geogrid installation elevates pavement performance by distributing loads, minimizing reflective cracking, and extending the pavement’s lifespan.

As a versatile and indispensable process, grinding assumes multifaceted roles across industries. Its fusion with geogrid technology amplifies its impact, particularly in construction and civil engineering. Understanding the nuances of grinding techniques and their alignment with materials and innovative technologies like geogrids underscores their significance in achieving precision, durability, and efficiency across diverse fields.