Metal Stamping: Investigating Precision in Advanced Manufacturing Techniques

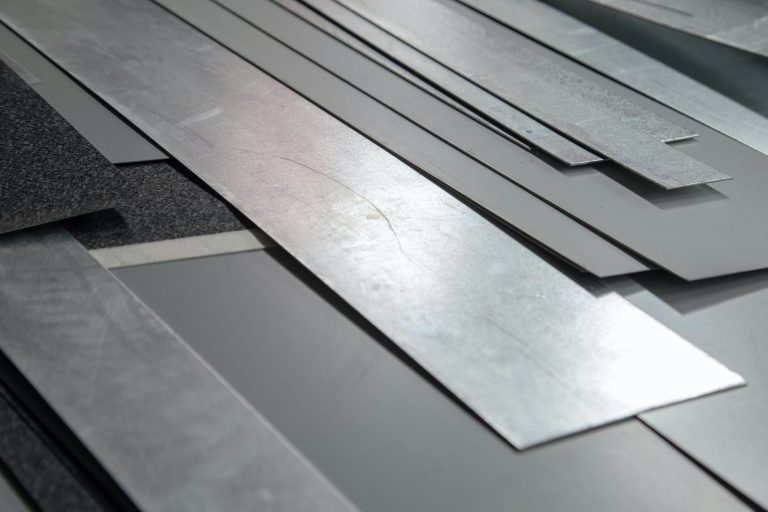

In the manufacturing domain, metal stamping signifies a revolutionary process that has transformed the creation of metal parts and components. Employing machinery and tooling, this approach molds flat metal sheets or coils into a spectrum of intricate designs and shapes. Its adaptability and precision have propelled its extensive integration across a multitude of sectors.

1. What precisely is metal stamping, and how does it function?

Metal stamping embodies a manufacturing method that converts flat metal sheets into desired shapes utilizing dies and presses. The process is initiated by inserting a flat sheet or coil of metal into a stamping press. Subsequently, the press applies significant pressure, shaping the metal into a die cavity, and adopting the desired part’s shape. This technique facilitates the creation of intricate designs and precise components with exceptional reproducibility.

2. What are some common applications of metal stamping?

Metal stamping finds ubiquitous application across various industries. In automotive manufacturing, it is essential for fabricating brackets, panels, and engine parts. In electronics, stamped metal parts serve as integral elements of connectors and housings. Aerospace industries rely on metal stamping to craft detailed components like brackets and fittings. Additionally, stamped metal parts play a significant role in household appliances, construction, and medical devices due to their functional durability.

3. What advantages does metal stamping offer in manufacturing?

Metal stamping offers numerous advantages. Primarily, it enables the rapid and cost-effective production of large quantities of parts. Its precision ensures consistent quality during mass production. Additionally, it accommodates various metals, including steel, aluminum, copper, and alloys, catering to diverse industry requirements. Moreover, the process minimizes material waste, presenting an eco-friendly manufacturing approach.

4. How does nonwoven geotextile align with metal stamping?

Nonwoven geotextile, while distinct from metal stamping, plays a pivotal role in construction and civil engineering projects. Geotextiles aid in soil stabilization, erosion control, and drainage systems. Although unrelated to metal stamping, their manufacturing principles align in precision and versatility. Both nonwoven geotextiles and metal stamping contribute uniquely to enhancing project durability and functionality.

In conclusion, metal stamping serves as a cornerstone in modern manufacturing, providing precise and efficient production methods across diverse industries. Its adaptability and proficiency in crafting intricate components establish it as an indispensable process in engineering and production.