Unlocking the Potential of Metal Stamping: Applications, Techniques, and the Role of Geosynthetics

Metal stamping is a pivotal manufacturing process that transforms flat metal sheets into specific shapes, catering to diverse industries. In this article, we delve into the intricacies of metal stamping, exploring its applications, techniques, and even its intersection with geosynthetics. Let’s unfold the world of metal stamping and its relevance in various sectors.

1. What is Metal Stamping and How Does It Work?

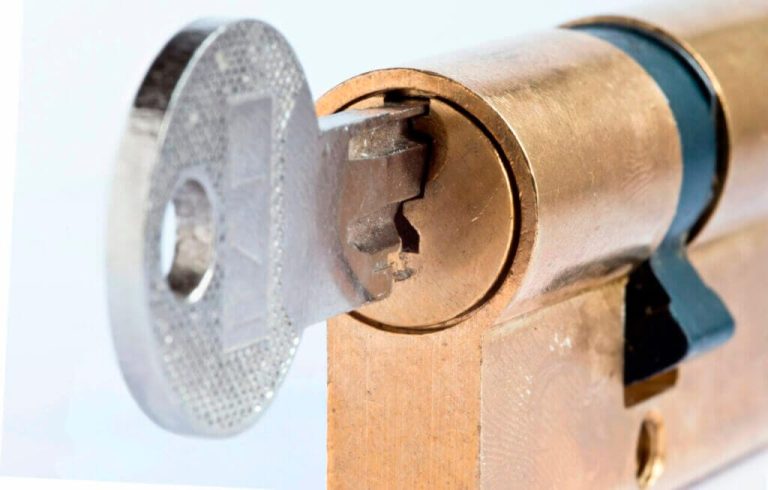

Metal stamping is a manufacturing process that utilizes various techniques like blanking, punching, bending, and piercing to convert flat metal sheets into specific shapes. The process involves placing the metal into a stamping press where a tool and die surface form the material into the desired shape.

2. What are the Key Applications of Metal Stamping?

Metal stamping finds widespread applications across industries such as automotive, aerospace, and medical. In the automotive sector, it is integral to crafting components like body panels and engine parts. In aerospace, metal stamping contributes to precision components. Additionally, the medical industry relies on metal stamping for manufacturing intricate parts used in medical devices.

3. How Does Metal Stamping Contribute to Geosynthetics Manufacturing?

Metal stamping plays a crucial role in the production of components for geosynthetics. For instance, in the fabrication of geotextiles, metal stamping techniques are employed to create precise components enhancing soil stabilization and erosion control. In the realm of geomembranes, metal stamping contributes to fixtures and connectors, ensuring secure installations and extending the lifespan of containment structures.

4. Can Metal Stamping be Environmentally Friendly?

Yes, metal stamping can be environmentally friendly. The process often results in minimal material waste, and manufacturers can use recycled metals. Additionally, the efficiency of metal stamping contributes to lower energy consumption compared to some alternative manufacturing processes, aligning with sustainable practices.

In conclusion, metal stamping stands as a versatile and crucial manufacturing process with applications spanning various industries. The seamless integration of metal stamping into geosynthetics manufacturing showcases its adaptability, contributing to the advancement of solutions in civil engineering and environmental projects. As industries evolve, the role of metal stamping continues to be a cornerstone in shaping the future of manufacturing.